Industrial Manufacturing Industry

Meilingge provides high-quality products and effective solutions to meet the needs of global industrial and heavy industry manufacturers. We are committed to providing industry-specific solutions, research and development expertise, global support, and product delivery to our customers. The patented technology product portfolio of Meilingge includes modular conveyor belts that can satisfy various application requirements, as well as our innovative intelligent sorting technology. This intelligent automated conveying system provides an optimized layout and can help customers solve the most challenging conveying problems cost-effectively.

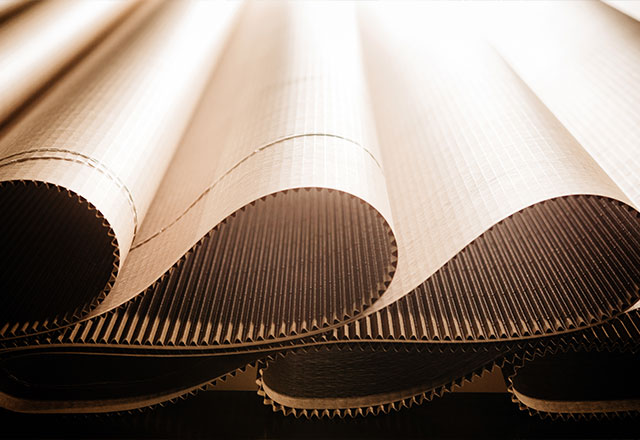

Corrugated Cardboard

Cardboard Handling

Innovative Structure

Superior Breathability

Smooth Surface, Wear-resist, and High-temperature Resist

High Temperature Resistance

Application Methods of Corrugated Cardboard Conveyor Belt

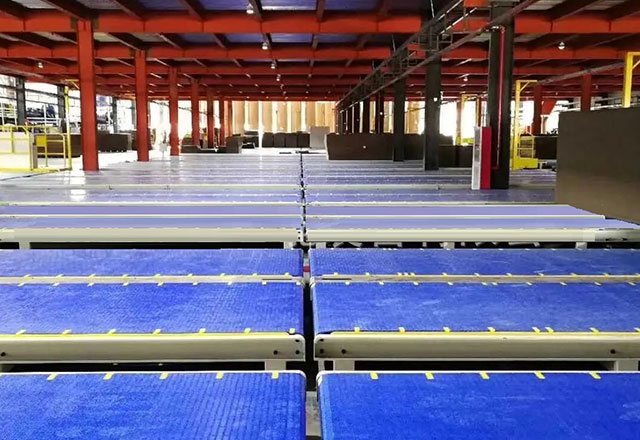

Advanced Modular Conveyor Belt Solutions

Advantages of Application in Corrugated Cardboard Conveyor Belt Projects

Designed to Meet Various Application Environments