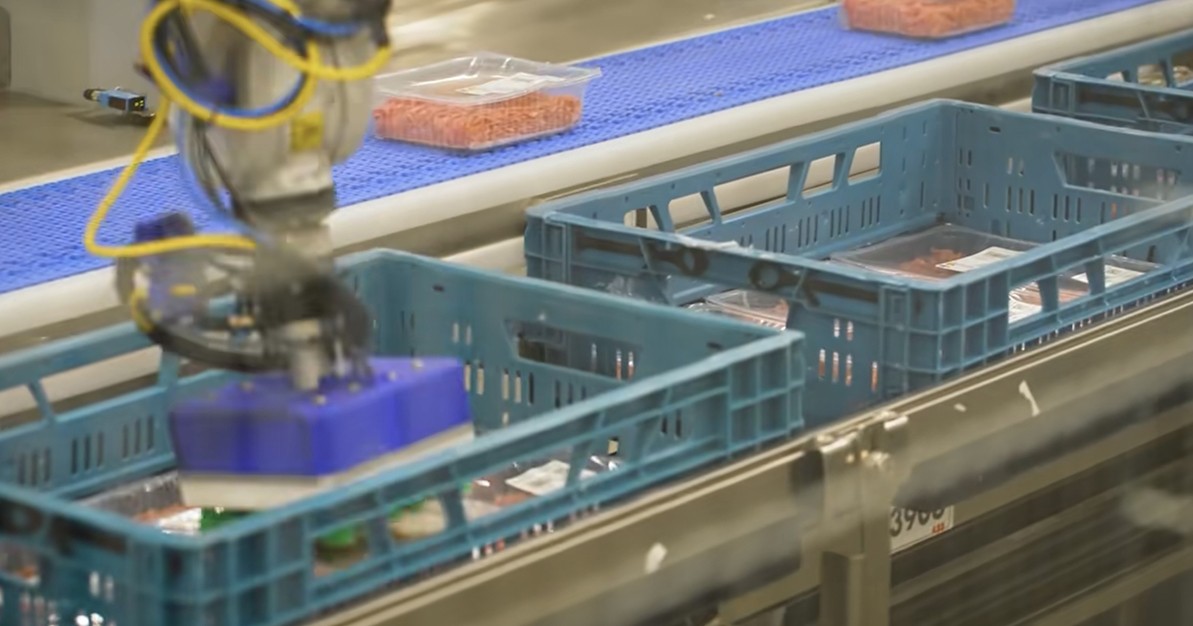

Food Industry

Industry Sore Points

1. High labor costs

Order increases, capacity expansion, high labor intensity, and labor costs.

2. Strict environmental requirements

Food processing technology has high requirements for environmental cleanliness. Fish, fresh food, and meat and poultry can produce foreign, increasing the risk of contamination to food health.

3. Severe food loss

Fish, seafood, and baked goods are prone to wear and tear.

4. Difficulty in machine cleaning and maintenance

The wear and tear caused by frozen, canned, and bagged food, the residues brought by the food itself, can easily lead to machine contamination and difficulty in cleaning.

Solution

Addressing the difficulties and challenges of food production lines with the right conveyor belt solution:

For the process scenarios of in the food industry. Meilingge has comprehensively considered the characteristics of durability, wear resistance, and drainage, and has launched a series of different specifications of modular conveyor belts and integrated flexible solutions to achieve intelligent, green, food, while also ensuring the reliable performance and long service life of the conveyor belt.

Advantages Of The Plan:

Meilingge's food conveyor belts and solutions can help you:

1. Prevent food pollution risks, ensure food safety and product quality;

2. It has the characteristics of smooth surface and anti sticking, can cooperate well with the scraper, and runs smoothly through sprocket drive;

3. Optimize operations to avoid downtime caused by conveyor belt or conveyor failures, improve production capacity and reliability;

4. Meilingge's food safety conveyor comes with a variety of materials and styles to choose from, ensuring product quality and brand integrity;

5. Easy to install, able to overcome complex and time-consuming cleaning and sanitation processes, and easier to clean and maintain;

6. Suitable for conveying high wear products and dealing with long-term production conditions, specially designed for conveying and sorting, ensuring the orderly progress of safe food;

7. Ensure efficient and non-destructive transportation, eliminate blockage issues, and improve operational efficiency;

8.Use professional technology to help customers optimize factories, applications and equipment.