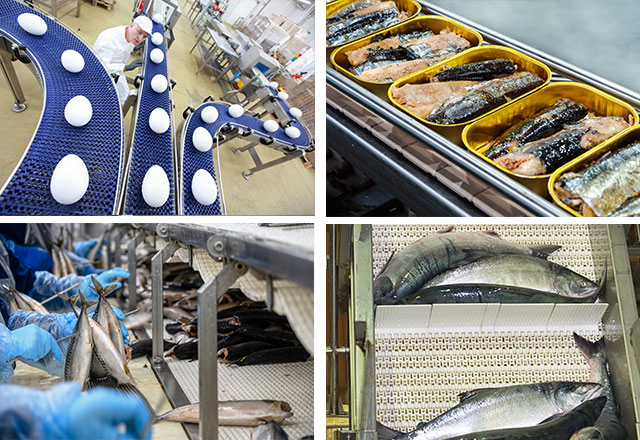

The Meat and Seafood Industry

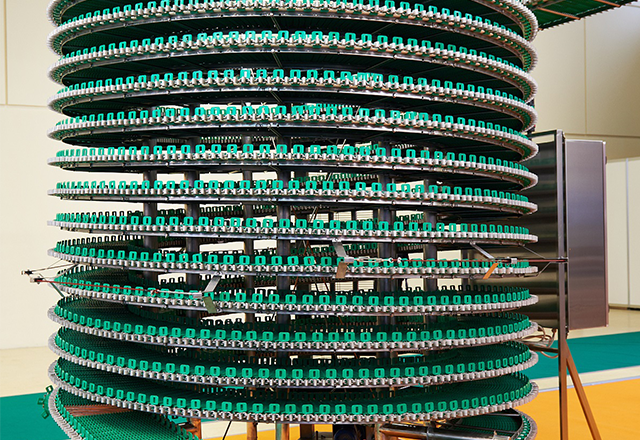

When you choose Meilingge to meet your needs for conveyor belts, you get more than just one supplier. We are still your business partner and have years of experience in developing solutions that can help you easily increase your company's revenue. In recent years, Meilingge has invented food modular conveyor belt technology, specifically designed to meet the special challenges of seafood processing enterprises. Subsequently, global meat, poultry, and seafood processing companies quickly realized the advantages of this technology. In the future Meilingge will also develop new and better methods to help customers improve production efficiency, improve hygiene conditions, and reduce conveyor belt ownership costs.

Meat, Poultry, and Seafood Industries

We can design transportation solutions for meat, poultry, and seafood processing enterprises

High Temperature Resistance, Non-sticky

Product Packaging and Flat Noodles Handling