Express Logistics Industry

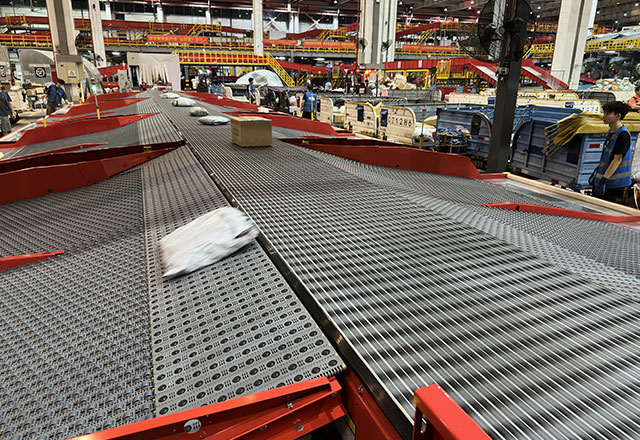

Meilingge's innovative conveying equipment can solve the most arduous challenges in logistics and material handling applications. The Meilingge intelligent sorting technology requires a smaller footprint, fewer equipment and controls, thereby reducing costs and enhancing functionality, significantly improving the layout of the production line. Intelligent sorting technology ensures fast and efficient handling of goods such as boxes, plastic packaging bags, packages, and large parcel bags. Meilingge technical experts can help optimize factory layout by simplifying sorting, merging, and single column processes. Our customer support center is composed of experienced application engineers, customer managers, and customer service representatives, capable of meeting the diverse needs of various fields in the logistics and material handling industry.

Logistics and Material Handling Industry

Parcel and Mail Handling

High Accuracy; Increase Production Capacity

Own Core Technology

No Wear or Impact on The Goods

Superior Equipment Performance Helps You Reduce Costs and Increase Efficiency

Efficient and Reliable; Intelligent Transmission

Building Core Competitiveness Solutions

Efficient 45° Sorting

Gently Conveying Various Types and Sizes of Packaged Goods

Batch Sorting - Automated Batch Sorting for Difficult-to-Handle Packages

Plastic Packaging Bag Conveyor

Unloading of Cargo Layers - Using Fewer Control Devices for High-speed Unloading of Pallets

Zone Picking