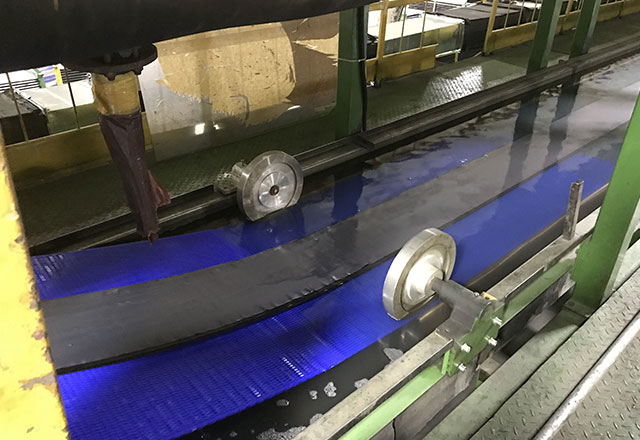

Tire and Rubber Industry

Meilingge creates enormous economic value for global manufacturers by providing integrated conveying solutions for the entire factory process, from mixing to finished tires. The comprehensive combination of Meilingge's products, services, and support can optimize your conveying system and factory layout, helping you achieve huge operational benefits and higher investment returns.

Tire and Wheel Assembly

Film Mixing and Compounding

Tire Molding

Vulcanization Process