Industrial Manufacturing

Industry Pain Points

1. Large fluctuations in business volume

Uneven busy schedule, during the promotion period, the warehouse needs to deal with a large number of orders with high efficiency requirements.

2. Diverse types of production equipment

There are many production processes, and the precision requirements for conveying and sorting methods and solutions vary for different industrial application scenarios.

3. Complex process route and strict environmental requirements

Products such as tires, rubber, and furniture have extremely high requirements for large and heavy loads, ensuring both efficient sorting and lossless high-quality conveying and sorting.

4. Low business fault tolerance

When there is a large volume of business and a large number of orders, errors are prone to occur. The diversification of transportation formats requires extremely high timeliness and accuracy.

Solution

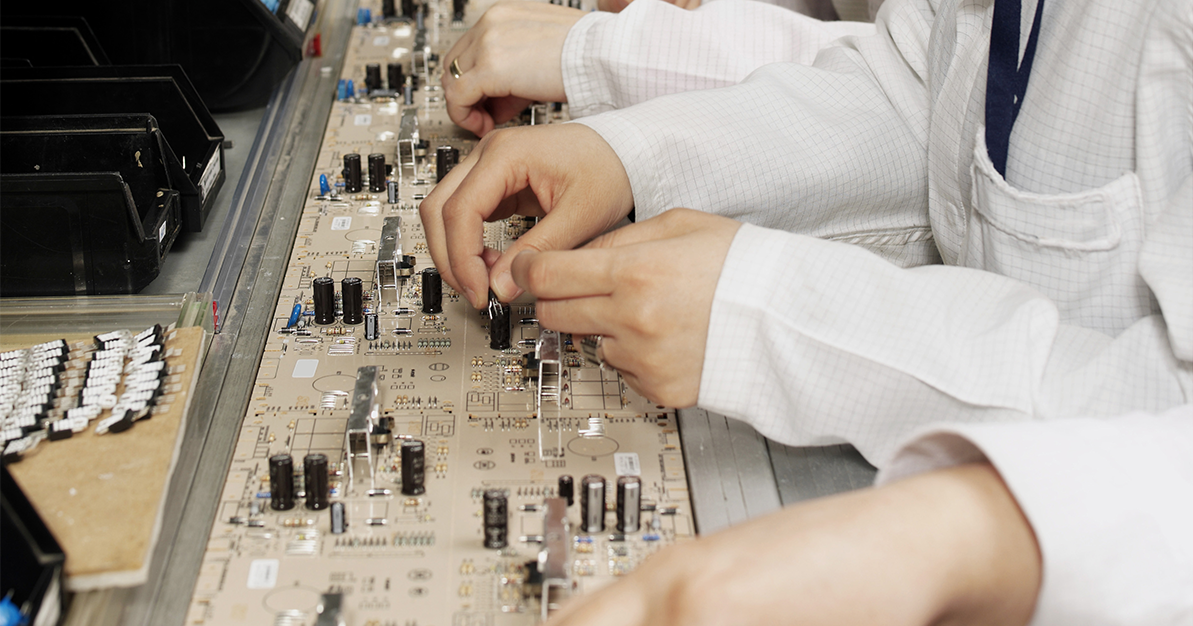

Meilingge's industrial conveyor belts aim for informatization, intelligence, and efficiency, comprehensively utilizing machines and labor to create a complete set of integrated scenario applications for product transportation, sorting, etc., effectively improving work efficiency and reducing labor, achieving true cost reduction and efficiency enhancement. Meilingge's turning conveyor belt can transport products with heavy loads and uneven loads, while saving factory space to adapt to small footprint factories. Meilingge's linear conveyor has smooth and anti slip-surfaces to choose from, ensuring smooth operation when conveying products and heavy objects. Meanwhile, Meilingge's conveyor belts and equipment can help manufacturers and processors in the tobacco, wood processing, textile, paper, and furniture industries improve operational efficiency in various challenging applications.

Advantages Of The Plan:

Meilingge's industrial manufacturing industry conveyor belts and solutions can help you:

1. It can efficiently and gently transport most types of products, avoiding the problems that traditional belt and steel plate conveyors may encounter;

2. Highly flexible and convenient for collaborative operation of multiple types of products, providing production efficiency and reducing product losses;

3. The conveying surface is easy to clean, install, and maintain;

4. Anti slip surfaces can improve the safety of workers and users;

5. Chain wheel engagement can prevent the conveyor belt from shifting, ensuring accuracy;

6. While reducing manpower, production waste are reduced caused by downtime of human errors;

7.Provide customized system services to meet the application needs of a variety of scenarios.